How Condition Monitoring Minimises Machine Downtime

It’s a word that manufacturing companies don’t want to hear: downtime. To some degree, downtime is unavoidable, for instance, when...

It’s a word that manufacturing companies don’t want to hear: downtime. To some degree, downtime is unavoidable, for instance, when...

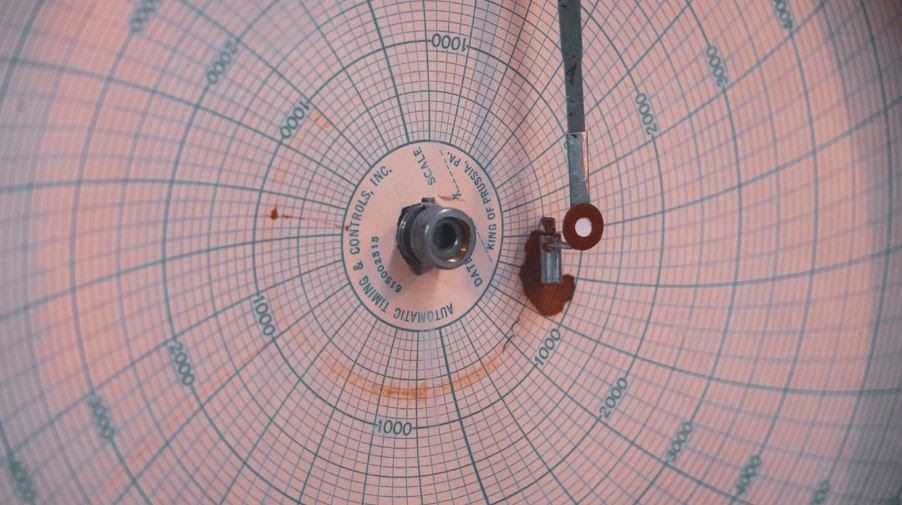

Condition monitoring equipment protects your machinery by providing early warnings when faults, inconsistencies, or irregularities are...

Online machine condition monitoring equipment has transformed power generation and oil & gas industries by improving turbine safety,...

Effective vibration monitoring can ensure your plant operates efficiently, cost-effectively, and within appropriate sound parameters –...

Automated, digitised turbine condition monitoring has revolutionised heavy industry and power generation by providing an 'all-in-one'...

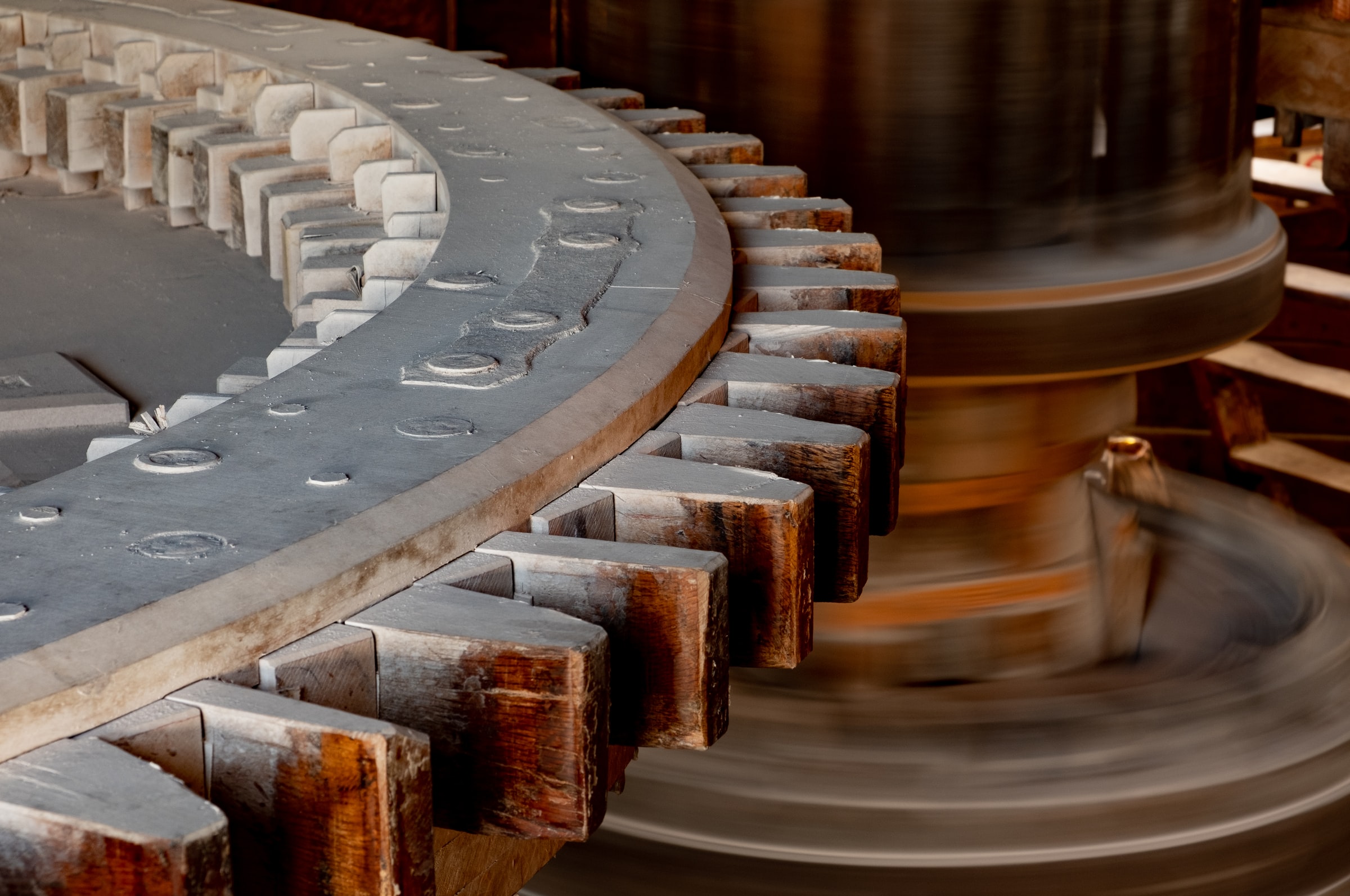

Moving machinery requires careful articulation in order to achieve optimum performance. However, rotating parts are prone to issues that...

Like all man-made structures, nuclear facilities are vulnerable to seismic events. As the 2011 Fukushima nuclear disaster showed, even...

Conditioning monitoring has been hailed as one of the all-time most important industrial innovations. However, many industrial sectors have...

SENSONICS ACHIEVES ISO 45001:2018 CERTIFICATION

In recent years, it has become increasingly apparent that critical industrial infrastructure is vulnerable to the forces of nature. As was...