Sensonics Consulting & Site Services

capabilities

Sensonics Consulting & Site Services

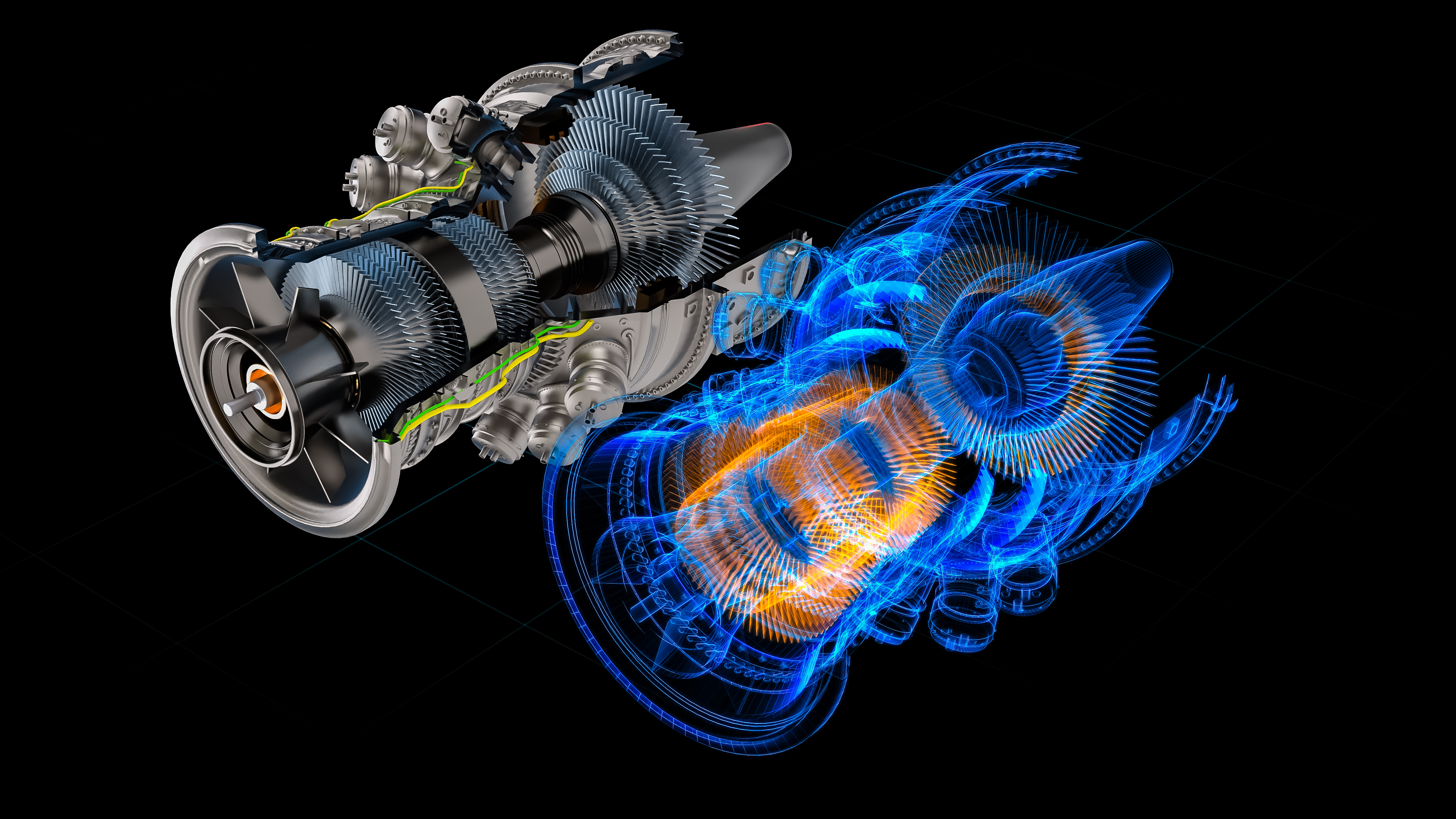

For rotating machine protection and seismic monitoring we offer the full design house capability from specification development through to equipment installation and commissioning.

Consulting

As a designer and manufacturer, we have the expertise to understand your measurement requirement and apply the appropriate instrumentation system.

We have the necessary mechanical, electrical and software design tools to provide customised solutions and over the years we have assisted many projects delivering vibration sensing solutions for challenging environments.

With a range of innovative products approved to IEC 61508, you can be sure of the best functionality with high reliability and ease of maintenance.

Site Service

Our site projects and engineering team have accumulated many years of experience on a wide range of plants. Installing and commissioning sensors and systems across most industries around the globe.

Refurbishment and modernisation of existing instruments is a specific area of expertise where our design and engineering facility enables customised solutions which are sometimes necessary for retrofit projects.

As an ATEX / IECEx approved designer and manufacturer we can advise on schemes for hazardous areas.

Where no fixed machine condition monitoring system is available (or is impractical) for critical plants, Sensonics recommend that periodic vibration data collection should be implemented to monitor and trend the operational condition of machinery. Offline analysis by our vibration experts can then identify faults and impending failures which enables the scheduling of maintenance to minimise downtime and loss of productivity.

We have service centres in the UK, India and China where we can offer a range of services including sensor calibration, equipment and factory acceptance testing.

Our Products

Download the engineers’ guide to specifying vibration monitoring systems

If you are designing a system which uses vibration monitoring then this guide can help you specify vibration monitoring systems.

This guide covers:

- Types of vibration sensors

- Monitoring equipment

- Questions to ask when designing or specifying a vibration monitoring system

- Why work with Sensonics

Please enter your details in the form to get your copy.

Get your copy