Quality & Environmental

Quality Assurance & Environmental Compliance

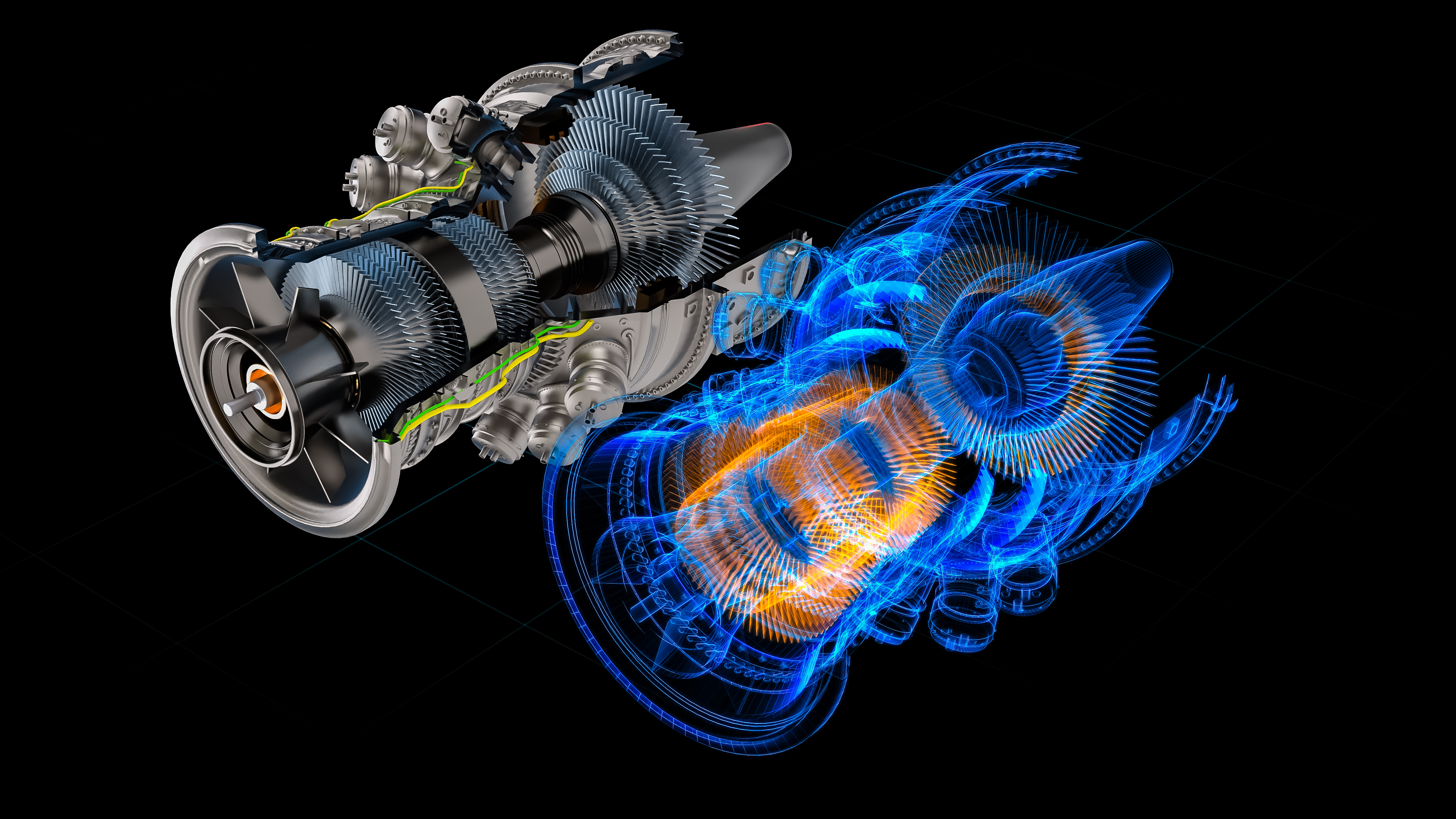

It is the policy of Sensonics Ltd to supply a range of products to its customers that will be safe, effective and reliable through life in the expected environment. Our market and customer focus is the supply of high integrity equipment and services for Machine Protection and Monitoring. This focus is reflected through our Quality objectives against which the company performance is measured and reviewed on a regular basis.

To accomplish these quality objectives, Sensonics has established, maintained, & implemented an effective Quality Management System which meets the requirements of ISO9001:2015. The management team has the responsibility and authority to continually improve, coordinate and monitor the implementation and effectiveness of this process based Quality Management System and customer feedback is actively sought to enhance customer satisfaction.

Have questions?

Talk to an expert

Our experienced Application Engineers are available to assist you in solving any problems that you may have concerning the choice and application of any of the Sensonics products in the measurement and control of vibration, position, temperature and proximity.

.jpg?width=177&height=250&name=EMS%20712749%20(2025-2028).jpg)

.jpg?width=177&height=250&name=MF26%20QESH%20Policy%20Statement%202025-2026%20-%20(signed).jpg)

.jpg?width=171&height=242&name=SGS%20UK%20QAN%200957%20(Expiry%2004-05-2026).jpg)

.jpg?width=171&height=242&name=SGS%20EU%20QAN%200957%20(Expiry%2004-05-2026).jpg)