Tackling Nuclear Product Obsolescence: Sensonics Providing Reliable Monitoring and Protection Solutions

As product obsolescence is fast becoming an increasing challenge within the nuclear industry, Sensonics is well-placed to provide long-term, reliable solutions. With over 40 years of experience in high-integrity protection systems for power turbines and seismic monitoring of critical infrastructure, Sensonics is highly capable in supporting nuclear facilities to mitigate the risks associated with obsolescence.

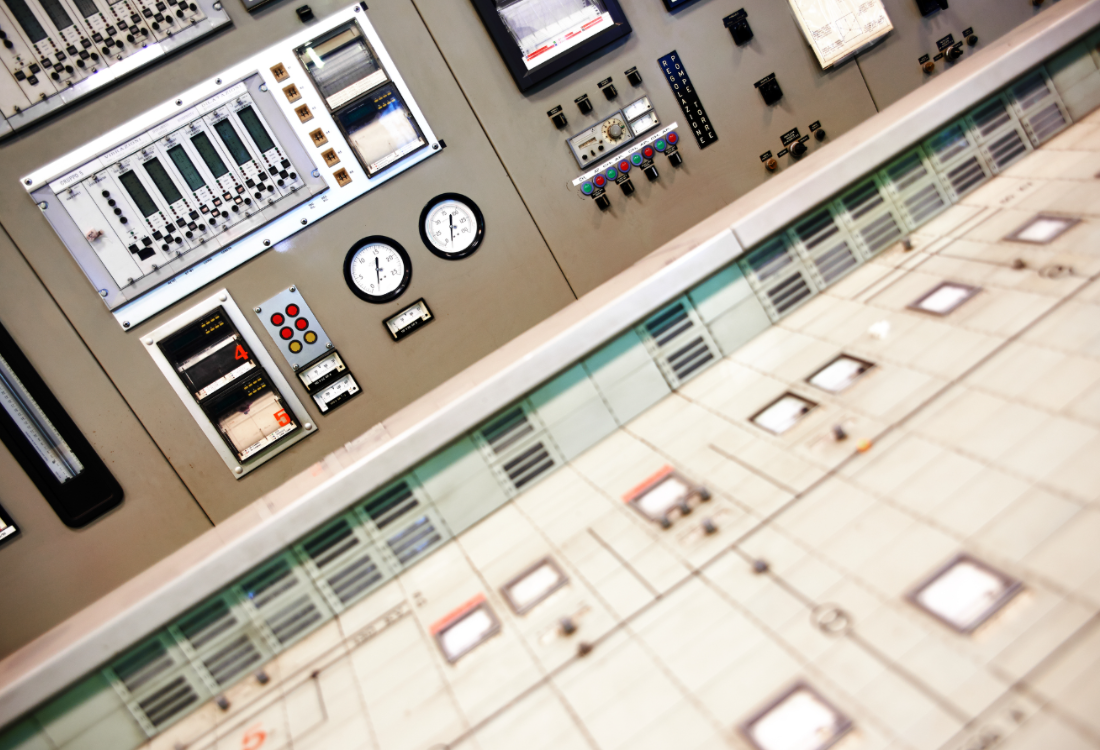

As most nuclear facilities have operated for many years, much of the equipment still in use today was installed during the original construction, with much of it well past the expected lifecycle. The fast-moving nature of development and manufacturing processes, together with limitations to supply chains, means that many original components are no longer manufactured or supported by the manufacturer. This gives rise to a very complex problem: critical systems face potential downtime, higher maintenance costs, and even safety concerns due to outdated or unsupported technology.

Obsolete equipment creates operational risks as obsolete components are highly susceptible to failure. The detection of such failures requires increasingly sophisticated monitoring. Replacement is prohibitively costly and often fraught with logistical challenges because legacy systems require custom parts or specialised expertise that are typically hard to source. Furthermore, strict regulatory standards call for modernisation of equipment; hence, facilities with obsolete systems should be prepared to incur additional costs due to compliance. Compounding the issue, manufacturers' phasing out legacy products leaves nuclear operators without essential support, forcing them to find alternative solutions to maintain safety and operational continuity.

Obsolescence, particularly in instrumentation and control systems, evidently constitutes a serious challenge related to the problems posed by outdated components, whose replacements will be increasingly unavailable. Thus, this could lead to an increase in maintenance costs and safety concerns, which are factored in decisions regarding facility shutdowns.

For instance, Michigan's Palisades Nuclear Plant was retired in 2022. In the lead-up to the plants retirement, safety measures were bypassed, and unresolved issues such as cooling system integrity and fire risk reduction were identified, indicating some of the issues when dealing with aging infrastructure.

Again, in the case of Indian Point Energy Center in New York, which went out of operation in 2021, reasons equating to a shutdown included old infrastructure and the difficulty involved in continuing operations with obsolete systems.

A Comprehensive Approach to Obsolescence Management

Through close collaboration with nuclear operators, Sensonics is uniquely capable in providing tailored solutions, from custom retrofits and modular upgrades to high-accuracy replacements, to accommodate seamless installations in existing infrastructure. These solutions are especially demanded in seismic monitoring and turbine protection, where absolute dependability is essential. Backed by a rich experience, Sensonics' instrumentation solutions are meticulously designed for durability and adaptiveness, thereby foundational in reducing the risk of equipment obsolescence.

Dedicated Expertise for Critical Infrastructure

"Our approach is all about assisting operators in realising more from their existing assets while improving safety and performance. We help mitigate the risks associated with obsolescence to let our partners in the nuclear industry keep operating with confidence and reliability with our robust protection systems and custom-designed solutions.”

[Russell King]

Long-term Partnerships for a Secure Future

Sensonics provides complete support, from consulting to first installation and ongoing regular maintenance, through upgrades of the system. That means as technologies change, Sensonics will continue to be a trusted partner in providing operators with effective obsolescence management solutions. These include comprehensive lifecycle management: design and installation of new systems, through ongoing monitoring and maintenance to modular upgrades. Sensonics takes a detailed view of each facility's particular operational needs to assist operators in developing obsolescence plans that assure seamless transition at the end of the lifecycle. This proactive approach helps minimise expensive downtime and supports continued regulatory compliance.

For more information, contact: