What Is the API 670 Standard And How Does It Benefit Electronic Overspeed Detection Systems?

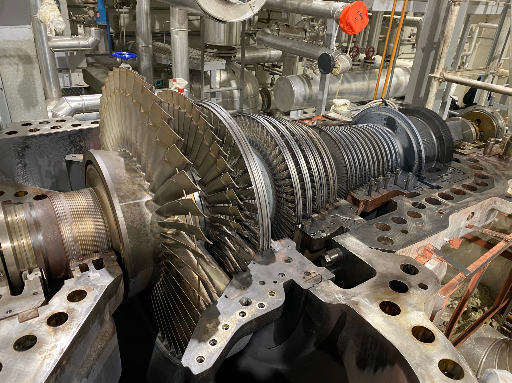

When a rotating machine experiences an overspeed event it means that it is likely to have exceeded its design limits, leading to potentially serious and costly damage to the machine, the plant buildings and infrastructure and even a life-threatening situation. The extent of the damage depends on two factors: how much the rotation exceeds design limits and for how long the event persists.

To prevent this situation from occurring, an overspeed detection system can provide early warning of an overspeed event so that instantaneous action is taken to shut down machinery quickly and safely.

What Is The API 670 Standard?

API 670 is an industry-standard that defines the minimum requirements for machine protection systems, covering all aspects of hardware, installation, testing, and documentation.

API 670 applies to a number of measurements, including electronic overspeed detection systems that comprise speed sensors, output relays, and power supplies to measure the rotation speed of the shaft and activate the relays if an overspeed situation is detected. The API 670 standard also applies to other aspects of machine protection, including vibration, axial shaft position, piston rod drop, and machine temperatures.

How API 670 Defines Electronic Overspeed Detection

API 670 relates exclusively to electronic overspeed detection systems, as mechanical systems are now generally obsolete. For overspeed detection systems to comply with API 670 standards, the following conditions must be met:

- The overspeed detection system must be isolated from other machine protection systems and must not share components, to verify that the system is functioning.

- The electronic overspeed detection system must have three independent measuring circuits. If overspeed is detected by two of the three sensors, the trip function will activate.

- The detection system may take forty milliseconds to detect overspeed and activate the relays, although, due to ramp-up, rotors may not exceed the design specification within this time.

Why You Should Invest In Sensonics Electronic Overspeed Detection Systems

At Sensonics, our high-quality overspeed detection systems ensure that our customers’ rotating machinery is protected against minor speed excesses that cheaper counterparts are unable to detect.

Our overspeed protection solutions offer:

- Low-speed sensing <1rpm.

- Self-checking and self-diagnostic capabilities.

- High visibility displays

- Response times <20ms

- Optimum positioning of proximity probes: wider spacing from the surface decreases the likelihood of them rubbing during abnormal vibration conditions.

Contact Us For More Information

At Sensonics, we offer reliable overspeed protection solutions for the power generation industry to prevent serious damage to rotors.

For more information or to discuss your business’s needs, please call us on 01442 876833 or send us your enquiry through our contact form.

Image source: Canva