Wind Turbine Condition Monitoring

Piezoelectric Accelerometers

Our expertise in sensing enables us to offer a low frequency response down to 0.1Hz with excellent noise performance providing the necessary dynamic range required for detailed analysis of gearbox vibration.

While our range of seismic sensors with high output sensitivity are suited for vibration monitoring of the tower structure.

-

Explore our range of piezoelectric accelerometers for wind turbines

Explore our range of piezoelectric accelerometers for wind turbines -

Explore our range of seismic sensors for wind turbines

Explore our range of seismic sensors for wind turbines -

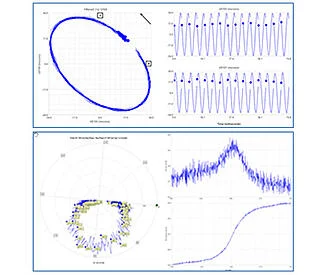

Internal turbine monitoring for blades, main bearings and gearboxes

Internal turbine monitoring for blades, main bearings and gearboxes -

SENSONICS engineers delivering AI-driven predictive maintenance

SENSONICS engineers delivering AI-driven predictive maintenance

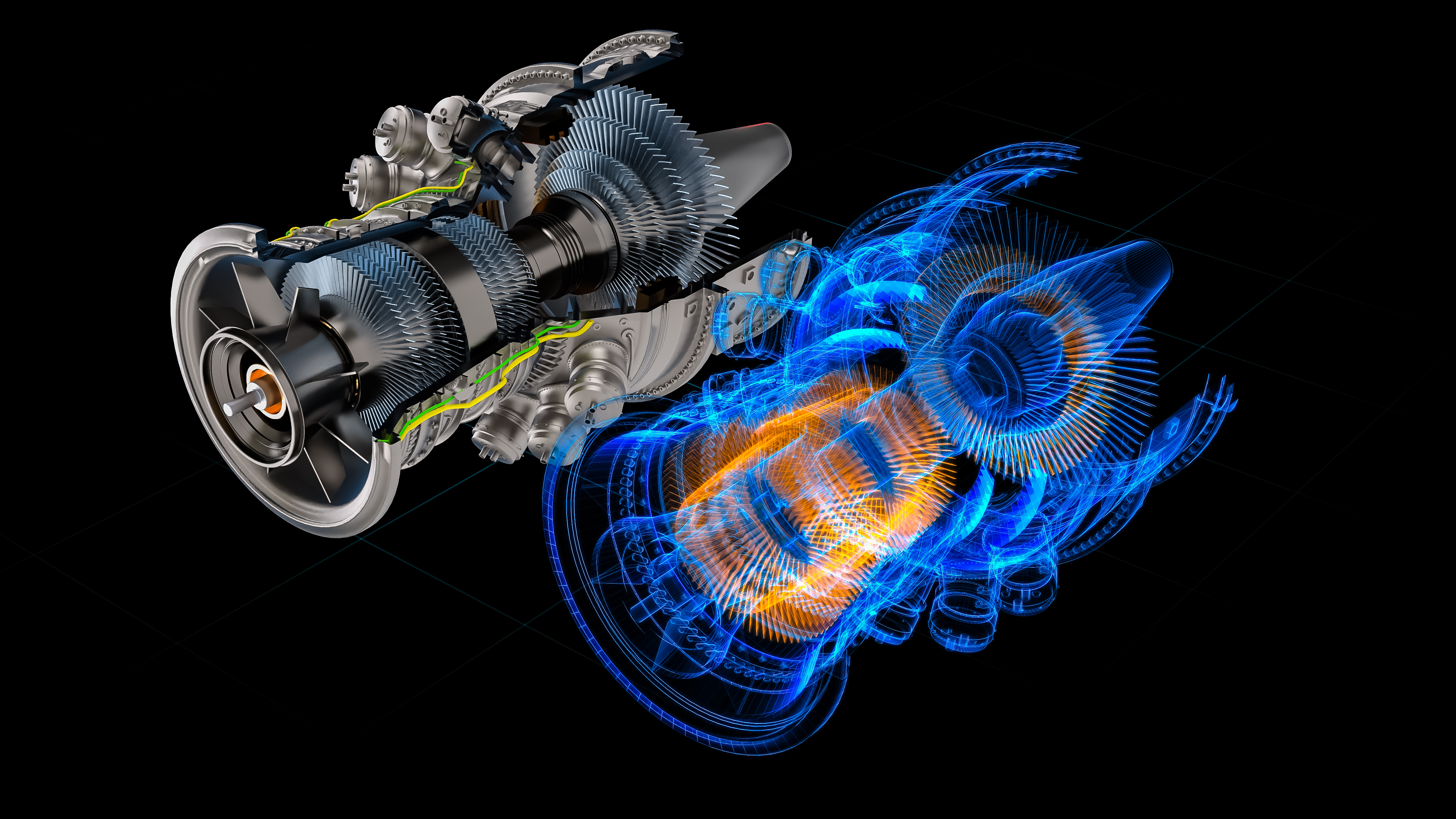

Optimising Wind Turbine Performance

Wind Turbine Condition Monitoring is the continuous process of tracking the operational status and overall health of wind turbines. By utilising advanced sensors, data analysis techniques, and monitoring systems, it enables the collection and examination of both real-time and historical data. The primary goal of condition monitoring is to identify potential issues or faults within critical turbine components early, allowing for timely maintenance or corrective actions. This proactive approach minimises the risk of failures, reduces downtime, and optimises the overall efficiency and performance of wind turbines.

.webp?width=350&height=379&name=Sensonics%20Turbines%20(1).webp)

MONTURWIND: Advancing Intelligent Condition Monitoring for Wind Turbines

MONTURWIND is SENSONICS’ ongoing condition monitoring project for wind turbines, bringing together non-intrusive sensing and AI-driven vibration analysis to detect early-stage faults across blades, main bearings and gearboxes. As the project continues to evolve, MONTURWIND is being developed to deliver deeper insight, proactive maintenance strategies and extended turbine life.

What's New

Latest news

Our Products

Download the engineers’ guide to specifying vibration monitoring systems

If you are designing a system which uses vibration monitoring then this guide can help you specify vibration monitoring systems.

This guide covers:

- Types of vibration sensors

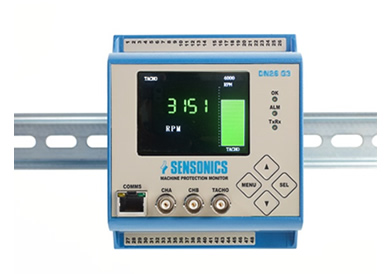

- Monitoring equipment

- Questions to ask when designing or specifying a vibration monitoring system

- Why work with Sensonics

Please enter your details in the form to get your copy.

Get your copy

What's New

Latest news

Our services

YOU MIGHT ALSO BE INTERESTED IN...

Turbine Supervisory Instrumentation

Industrial Sensors

Speed Monitoring Solutions