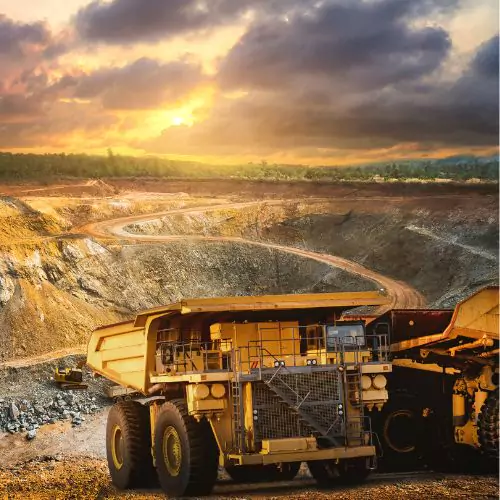

Mining & Metals

Our Industries Expertise | Sensonics

Mining & Metals

Sensonics has a large number of equipment references in the Mining and Metals industry. From vibration monitoring on air handling equipment in mines and blast furnace blowers through to turbine supervisory measurements on heat recovery turbines in iron and steel processing plants. We have the experience and products to ensure safe operation on a wide variety of equipment.

Our sensors and systems are designed for harsh conditions and can be found monitoring bearing vibration, shaft vibration & position, thrust wear and rotational speed on a wide range of turbines, pumps, fans and compressors. Now operating on our third generation hardware platform Sentry G3, the most advanced machinery protection system available on the market.

Power Plant

Sensonics instrumentation offers both monitorings of the dynamic behaviour of rotating machines as well as providing the essential measurement interlocks guaranteeing smooth operation of the power plant.

Our range of vibration sensors offers both piezoelectric and electrodynamic velocity sensing options for the measurement of bearing and casing vibration up to temperatures of 450°C.

Sensonics Senturion X range of proximity probes comply with the API 670 standard and are available with direct 4-20mA processed outputs for vibration, shaft position and speed monitoring.

To provide the sensor signal conditioning our Sentry G3 supervisory system has tailored measurement algorithms for both steam and gas turbine applications.

Condition monitoring is available through our optional CMS plugin providing a suite of analysis tools to monitor the detailed dynamic behaviour of the turbine set.

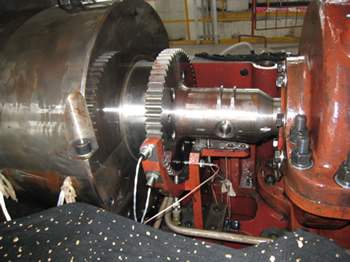

Air Handling

Sensonics offer a wide range of instrumentation to suit compressor and blower machinery utilised in the metals industry. Our sensors are approved to both ATEX and IECEx standards offering the highest levels of protection and with API 670 standard compliance across the product range our measurements are also compliant with ISO vibration standards.

Vibration sensor options include piezoelectric accelerometers, velocity sensors and proximity probes. Available with direct 4-20mA processed outputs for vibration, shaft position and speed, a very cost-effective method for less critical plant monitoring. To provide additional functionality such as shutdown protection (large multistage compressors) and digital communications our Sentry G3 supervisory system, or our DN26G3 monitor which is ideal for local machine panel integration, is both cost-effective solutions.

Our Products

Download the engineers’ guide to specifying vibration monitoring systems

If you are designing a system which uses vibration monitoring then this guide can help you specify vibration monitoring systems.

This guide covers:

- Types of vibration sensors

- Monitoring equipment

- Questions to ask when designing or specifying a vibration monitoring system

- Why work with Sensonics

Please enter your details in the form to get your copy.

Get your copy