Defence

Our Industries Expertise | Sensonics

Defence

Sensonics partners with the defence industry supplying specialised instrumentation solutions for power turbine, engine and pump condition monitoring as well as seismic protection and event recording for dockside infrastructure.

Our sensors and systems are designed for defence applications and can be found monitoring bearing vibration, shaft vibration & position and rotational speed on turbines and pump plants. Our seismic protection and recording equipment is used for the vibration monitoring of critical infrastructure. As the leading supplier of seismic monitoring and protection systems to the UK nuclear-licenced sites we have solutions to meet with a diverse range of applications providing safe shutdown and recording facilities in the event of an earthquake.

Power Turbines

& Pumps

Sensonics instrumentation offers both monitorings of the dynamic behaviour of rotating machines as well as providing the essential measurement interlocks for the smooth operation of the power and pumping plants.

Our range of vibration sensors offers both piezoelectric and electrodynamic velocity sensing options for the measurement of bearing and casing vibration with operation up to 450°C. The Senturion X range of proximity probes comply with the API 670 standard and are suitable for vibration, shaft position and speed monitoring.

To provide the sensor signal conditioning our Sentry G3 supervisory system has tailored measurement algorithms for both steam and gas turbine applications. Critically offering SIL-3 over speed protection, which is a key requirement for defence applications.

Seismic

Structural vibration monitoring of dockside infrastructure is an essential protection requirement for nuclear licenced sites. Our equipment can be found providing seismic protection for cranes, lifting plants and other transportation systems.

Alarm management and event capture is achieved through our seismic sensors in combination with multichannel recording equipment providing time history, FFT and spectral response analysis.

Integrity and robustness is key to our system concept, with protected power supply configurations, custom indication panels, as well as 2 of 3, voted alarm processing suitable for safety-critical applications.

Safety Systems

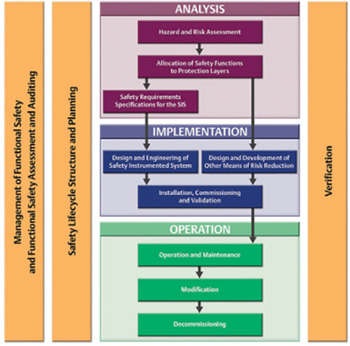

We are not just sensing experts providing condition monitoring for critical rotating machines and infrastructure, many of the systems we provide have a protective element for safe shutdown in the event of excessive vibration or over speed occurrence (as an example).

For this reason, many of our product lines can be provided with stated reliability backed up by field data with inbuilt facilities for proof testing. Offering the complete design service we can supply vibration, position and speed protection systems to comply with IEC 61508 up to SIL-3.

Contact Sensonics for further details.

Our Products

Download the engineers’ guide to specifying vibration monitoring systems

If you are designing a system which uses vibration monitoring then this guide can help you specify vibration monitoring systems.

This guide covers:

- Types of vibration sensors

- Monitoring equipment

- Questions to ask when designing or specifying a vibration monitoring system

- Why work with Sensonics

Please enter your details in the form to get your copy.

Get your copy