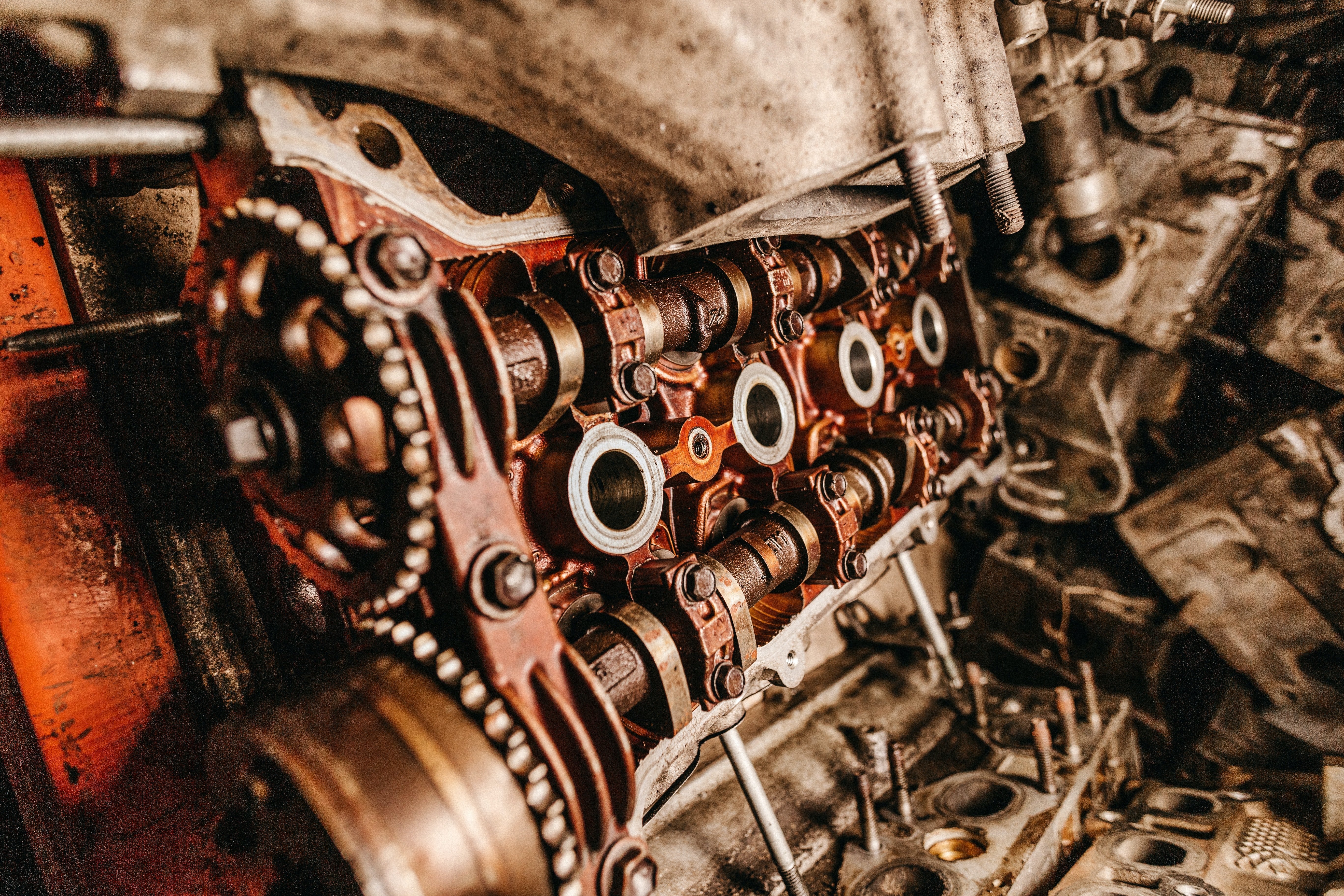

Process Condition Monitoring – A Key Technique To Prevent Machine Failure

Process condition monitoring (PCM hereafter) is a technique used to check complex, industrial machines for developing faults while they're in use. By using an array of electronic sensors tailored to each machine to monitor temperature, vibration, and alignment, moving parts can be carefully tracked for overall performance and any anomalies.

Once a potential fault is detected from data that shows deteriorating performance, preventive maintenance can be scheduled. The machine is repaired or retooled to prevent the unit from developing a worsening flaw or breaking down altogether. PCM is extremely useful for machines that see high amounts of uptime, need to be precisely optimised for maximum performance, need to be kept in an 'always on' state, or are subject to huge amounts of thermal stress and mechanical wear.

Planned Maintenance and Process Condition Monitoring

PCM is used in industries large and small worldwide, although the nature of how PCM is performed may vary greatly between companies and equipment. The one connecting thread is that all PCM styles rely on a network of sensors to measure different stress factors affecting the machine they're attached to.

The result is a maintenance schedule that addresses problems when they need to be addressed – as opposed to simply planning maintenance on set dates, or after every X operating hours, which is what most planned preventative maintence schedules do. The goal of planned maintenance is to flag up and resolve any mechanical issues ahead of time by monitoring machines for micro-scale changes to the machine's performance and calibration, and PCM has the same objective.

However, the problem with the planned maintenance approach, and why process condition monitoring is so much more efficient, is that planned maintenance could miss issues that develop between services, or could needlessly take plant offline when there are no current maintenance issues.

Planned maintenance is designed to reduce unplanned downtime on critical plant, but generally involves more scheduled downtime and longer maintenance sessions, which could impact productivity and profits. It's also far more labour and cost-intensive than other methods. The Planned approach requires more money to be spent on replacement parts to work correctly.

There are two ways in which PCM can be used to enhance machine lifespan and prevent damaging faults – through predictive or reactive maintenance.

Predictive Maintenance

Predictive maintenance uses various condition monitoring sensors to schedule machine downtime when sensor data indicates that the machine is at risk of developing a critical fault. Your sensors will detect if clearance is getting too small, or pressure is getting too high, or something is getting too hot – avoiding the need for uneccessary maintenance when things are running fine, and making it quicker to replace components that are approaching end-of-life.

A critical fault is defined as anything that could permanently stop or break the machine or drop the machine's productivity below a set 'floor'. These 'stop' parameters are defined ahead of time for each process by engineers.

Predictive maintenance's main advantage is that it saves time, money, and effort while keeping machines running effectively and minimising downtime. It's also easy to integrate into production as a semi-routine exercise and won't tie up your maintenance staff every two seconds with minor PCM repair jobs. However, there are still ongoing costs for replacement parts - Predictive Maintenance won't eliminate standard machine fatigue and repair fees.

Reactive Maintenance

The 'hands-off' approach. Sensors are installed and used only for safety and security reasons – and you react to anomalous sensor readings and machine faults without scheduling maintenance at any other time. When a fault is detected, downtime is scheduled and the machine is then repaired or wholly replaced. Reactive maintenance frees up time, money, and staff attention to focus on more pressing tasks.

This technique is usually only appropriate when the critical machines are in duplex format, i.e. 100% redundancy, so in the process only pump A is operating and pump B is on stand-by ready to be called into action if pump A has a problem, or perhaps there is a situation where 6 fans need to be running to achieve 100% output when 8 fans are available. Relying on reactive maintenance is a very risky strategy for a critical machine train if there is no redundancy for any one machine. It can also result in higher one-off costs when a machine has to be repaired – it is often cheaper to addess the warning signs through predictive maintenance that to wait and address the fault itself. It's also a poor strategy for planning and optimising complex mechanical systems and may endanger staff and machinery if used with high-stress equipment.

Process Condition Monitoring Sensors from Sensonics

At Sensonics, we manufacture a wide range of standard sensors for PCM strategies, and also offer adaptations and completely bespoke design solutions where standard does not fit the bill. To discuss your requirements with one of our engineers, please get in touch today by phone or email.

Image Source: Unsplash